-40%

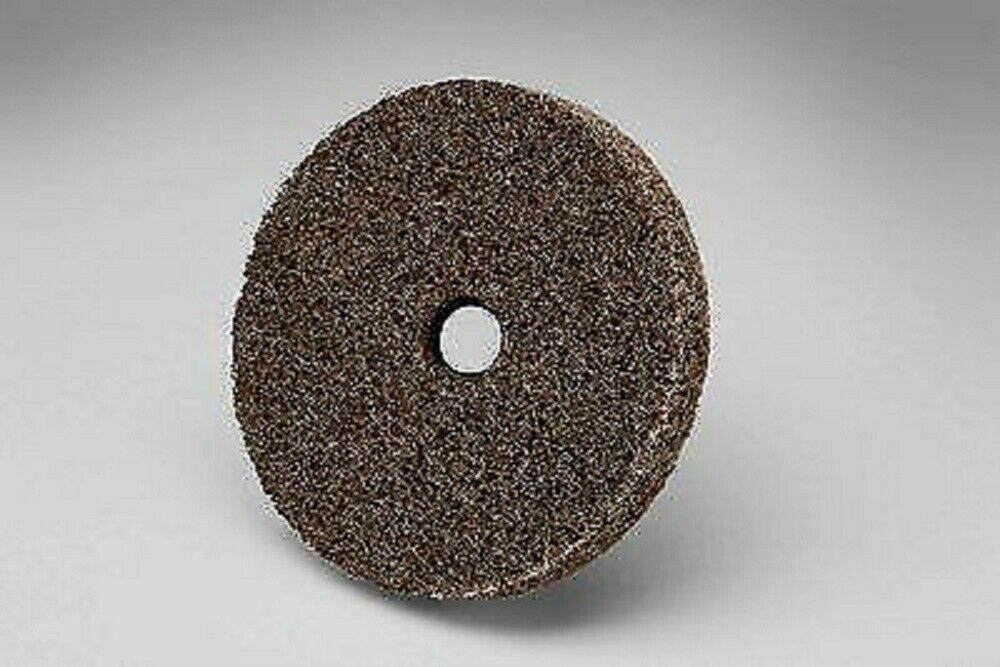

6 Each 3M/Standard Abrasives 4"x1/4"x1/4" 881154 811 A/O Unitized Wheel 35634

$ 36.95

- Description

- Size Guide

Description

Standard Abrasives™ A/O Unitized Wheel 881154, 811 4 in x 1/4 in x 1/4 inCombining a high density wheel with medium or coarse mineral results in superior edgework deburring and polishing

Harder material density and increased edge durability over 700 Series Unitized Wheels increases life for heavy-duty tasks

Aluminum oxide mineral is a good match for ferrous and non-ferrous metals, including aluminum

Runs clockwise and counterclockwise, allowing greater versatility when paired with tools and machines

Open web is load resistant, contributing to longer abrasive service life

Center hole wheel comes in a range of diameters from 1-6˝ and attaches to tool with a unitized wheel mandrel (sold separately)

Our Standard Abrasives™ Aluminum Oxide 800 Series Unitized Wheel is a hard density wheel designed with extra tough edge durability, making it a good match for heavy-duty edge deburring and stainless steel polishing applications.

Hard Density Abrasive Wheel Removes Challenging Burrs with Precision and Imparts a Fine Polish

Our Standard Abrasives™ Aluminum Oxide 800 Series Unitized Wheel is offered in two grades of aluminum oxide (A/O) mineral: coarse or medium. The hardness of this wheel places it on the upper end of the spectrum of aggressiveness among Standard Abrasives™ Unitized Wheels. Given the coarseness of the mineral and the greater density, this wheel is able to withstand high-pressure applications and cut aggressively, making it well-suited for deburring and polishing applications.

Use our Standard Abrasives™ 800 Series Unitized Wheel for deburring stainless steel pipe thread, wire edges from surgical instruments, stainless steel sinks, tanks and other equipment for the food service industry. It is a prime choice for deburring gears and aircraft wing spars, and breaking edges on aluminum extrusions. When it comes to polishing, trust the 800 Series A/O Unitized Wheel to effectively polish stainless steel rule dies, welds on stainless steel sinks, machined surfaces, hand tools and round tubing.

Compatible with a Variety of Tools

Unitized wheels are typically used on a die grinder. A benefit of unitized wheels is that they are bi-directional and can be mounted on a tool or pedestal grinder without regard to the direction of the spindle rotation. This means the Standard Abrasives™ Unitized Wheel can be used with a variety of tools, and regardless of which way the workpiece is fed through the machine, the wheel will be able to respond, giving operators more flexibility. The stiffness of the unitized construction enables operators to use thinner wheels to access awkward angles with grinding tools.

Series 800 wheels comes in a range of diameters from 1-6˝ and requires a unitized wheel mandrel (sold separately) for attachment to the tool. Quick change wheels are also available (sold separately).

Non-Woven Unitized Construction Offers a Step Up in Density and Durability for Stubborn Surfaces

Standard Abrasives™ Unitized Wheels are a great match for tough deburring, cleaning, blending and finishing applications. They come in a broad range of densities and grades to suit different metals, the degree of aggressiveness required, shape of the part, and desired finish. Although used for some of the same tasks as Standard Abrasives™ Buff and Blend products, they are designed with a far stronger and denser construction to support more aggressive applications and accomplish material removal more rapidly. Even though unitized wheels are much stiffer products, the non-woven nylon fibers of the wheel maintain the advantage of responding to surface irregularities while preserving the geometry of the piece, and produce a consistent finish.

Unitized wheels are created by starting with layers of open web material that combines non-woven fiber strands and abrasive mineral with a tough resin bond. These layers of web are then cured and compressed together. By fusing layers of open web, the abrasive gains more toughness and durability, so it can withstand repeated wear.

Ultimately, the wheel's durability is what makes it such a good match for edges. Regardless of the diameter or thickness of the wheel, it maintains its structural integrity to remain a stiff and long-lasting abrasive even under high pressure. Additionally, as the layers wear, the wheel can be dressed to maintain its shape.

Load-Resistance Boosts Life and Performance

Standard Abrasives™ Unitized Wheels are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Non-Woven Products

Standard Abrasives™ Unitized Wheels offer many benefits for heavy-duty jobs. For all the aforementioned reasons, Standard Abrasives™ Unitized Wheels invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput.

Brand

Standard Abrasives™

Abrasive Material

Aluminum Oxide

Attachment Type

Center Hole

Center Hole Diameter (Imperial)

0.25 in

Center Hole Diameter (Metric)

6.35 mm

Density Rating

Hard

Face Width (Imperial)

0.25 in

Face Width (Metric)

6.35 mm

Grade

Coarse

Overall Diameter (Imperial)

4.0 in

Overall Diameter (Metric)

101.6 mm

Overall Width (Imperial)

0.25 in

Overall Width (Metric)

6.35 mm

Product Form

Wheel

Not Out of A Garage

APD Incorporated is one of the largest independent authorized 3M industrial products distributor in the United States. We are also one of the few vertically integrated industrial products suppliers around. In addition to distributing for top industrial brands such as 3M, Norton, Dynabrade, and VSM just to name a few, we also design, convert and manufacture innovative abrasives and tape products in Southern California. We are headquartered in Corona, California.

Serving the Professionals

APD Incorporated serves customers on the industrial and professional levels. We are ill equipped to service DIY customers and customers that only focuses on unit cost of a particular product-type.

Mission Possible

On eBay, APD Incorporated aims to provide a complete range of industrial abrasives, adhesives and tapes to our customer base. If you can't find something, please ask us and chances are we can fulfill your needs quickly and cost-effectively. We are a good resource to bookmark and follow.

Communicate with Us

APD Incorporated is set up to process e-transactions and e-communications. Please do not call us outside of eBay messaging system. It is the easiest to contact us through eBay messaging than to call us.

Return Policy

Please choose your products carefully and ask questions if you are unsure to help us maintain our low pricing levels. We offer high performance professional products at thin margins for professional and industrial users with knowledge of these products. Buyer pays return shipping on listings indicated returnable. In case of APD Inc error, we will pay for the return shipping. Returns are valid within 30 days of product receipt.

Photos

APD Incorporated offers thousands of products on eBay and sometimes we must rely on manufacturer stock photo or sometimes there may be errors in the photos. Our item name and description are always used to judge correctness over photos. Please ask us to upload and update photos to particular listings of interest if you need them and we will be happy to do so.

Shipping

APD Incorporated offers a variety of products with different lead time. Products can ship from 1 business day up to 10 so please be mindful of the lead time we state in our listings. There is no default shipping lead time.

Packaging

APD Incorporated reserves the right to modify original manufacturer's packaging where applicable to continue to offer free shipping on most listings at a lower than market cost. Shipping is a big portion of the cost associated with selling, we will normally combine or optimize packages to lower shipping charges.

Resellers

APD Incorporated services end-use customers on eBay. We discourage resellers from purchasing from us as we cannot always meet our customers' customers unspoken conditions.

Unfair Practices

APD Incorporated actively block buyers from future transactions that unfairly holds us responsible for issues stemming from buyer errors.

Thank You

APD Incorporated thanks you for your support. We hope you will enjoy and help us become a better full range supplier for you. Your comments and questions are always welcomed. Keep producing and keep dreaming, we will work hard to support your efforts.